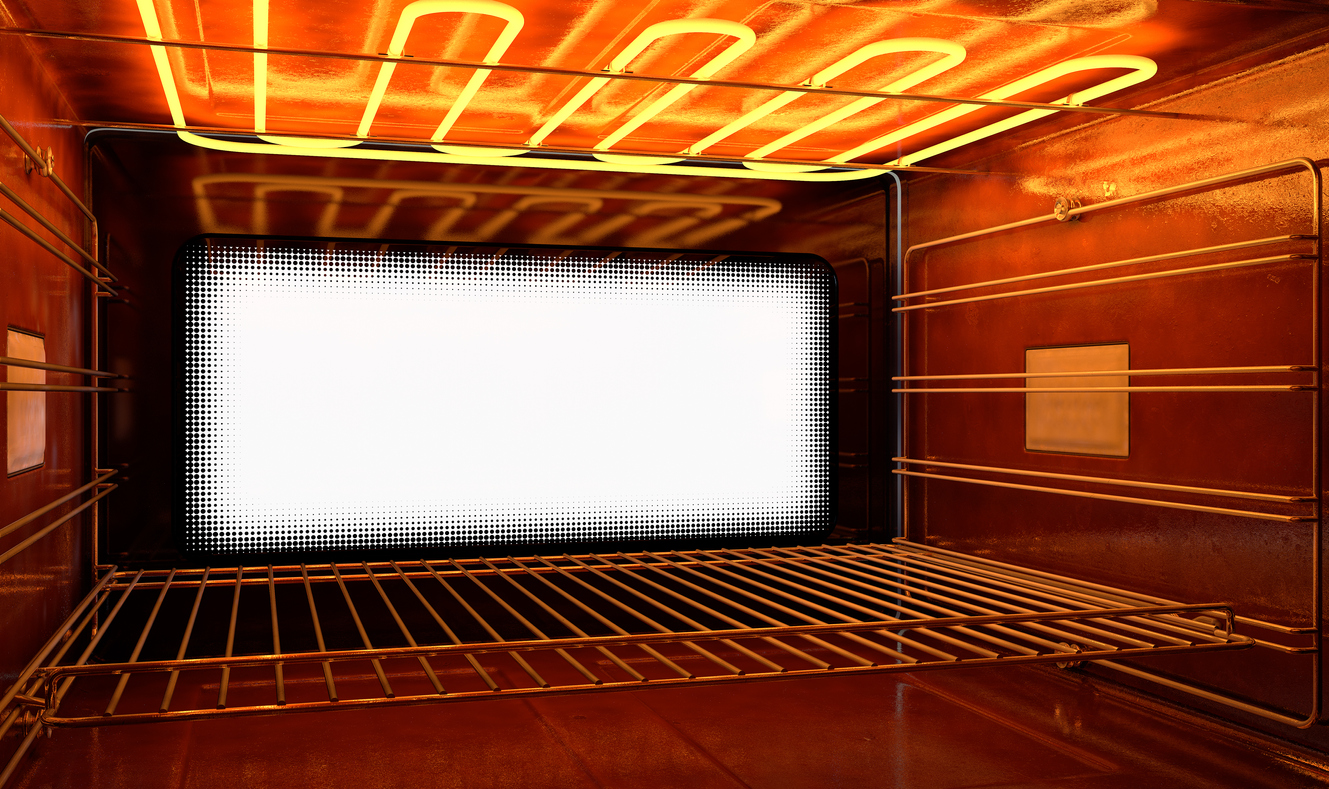

Low-Emissivity and Double-Low-Emissivity glass are typically used as inner and intermediate doors in domestic and professional ovens; starting from the customer’s technical specifications, they are cut to size and subjected to edge processing and screen printing. This printing can be performed on the coating side or on the opposite side.

The use of Low-Emissivity Glass as the first glass exposed to the cavity in pyrolytic ovens requires a highly fragmented tempering process, in order to increase the thermal performance of the glass which, being a float-based glass, is not in any case comparable to borosilicate glass.

ILVA Glass has in its portfolio a very wide variety of glass for oven doors with low-emissivity coating, which allows a high flexibility in the design phase of the oven by the customer.

Starting from the classic Low-Emissivity Glass for building use, we can supply glass with a coating based on:

- FTO (Flourine Tin Oxide)

- ITO (Indium Tin Oxide)

- Silver Coating

- ITO with protective coating